The 2022 World Cup begins with something unprecedented in the history of football: a stadium entirely made of containers, known as Stadium 974. Created to facilitate logistics and protect cargo, containers have, over time, gained other uses – whether in civil construction, trade, or art. The versatility of these metallic boxes allows them to permeate various sectors of the economy other than just foreign trade.

Containers at the Qatar World Cup

Located in the city of Doha, Stadium 974 features a different architectural concept, which the organizers of the Qatar Cup commissioned to Fenwick Iribarren Architects.

The plan was to prevent the 40,000-person stadium from becoming a white elephant after the tournament. The proposed solution revolved around creating a structure that allows the 974 containers that make up the stadium (hence its name, also a reference to the Qatari phone code) to be removed and assembled in other places.

Stadium 974 will be the stage for Brazil’s national football team match against Switzerland on November 28 at 1 pm, the second round of the group stage.

Curiously enough, the stadium may be re-installed in another country after the world event or be turned into an arena for 20,000 or 30,000 fans in Qatar itself.

The corridors behind the stands area all made of containers, with no regularity between the walls.

Another interesting characteristic is that the sections of the stadium are color-coded. For example, yellow containers stand for toilets, while green ones indicate the presence of an ambulatory. Seating information is all painted on shipping containers with a ship reference.

According to the stadium director, Mohamed Al Atwaan, 30,000 tonnes of steel were used in the construction. According to him, the 974 will host matches until the round of 16. The containers are easy to transport and have been manufactured specifically for use in the stadium.

Despite being the only stadium without artificial air conditioning in the stands, the 974 has full internal climatization systems and giant fans spread throughout the structure.

Despite being the only stadium without artificial air conditioning in the stands, the 974 features full internal climatization systems and giant fans throughout the structure.

Containers in civil construction

Containers were used in housing construction long before they were used in football stadiums. In this case, one of the main advantages is the speed of construction, as structures in containers take 60 to 90 days to complete, whereas a traditional house takes 5 to 8 months. In addition, using containers also makes earthmoving work easier and more sustainable.

Other uses attributed to containers in civil construction are as toilets during events and at construction sites, providing more comfort than chemical toilets, in addition to being used as event booths, itinerant stores, and restaurants. There is also a worldwide trend of containers being included in the composition of works of art.

A little bit of history

Containers were an invention of the American businessman Malcolm McLean, owner of a small trucking company who, in 1937, had the idea of creating steel boxes that could be easily transported from end-to-end when watching bales of cotton being loaded onto a vessel.

Before that, products were packed in barrels or crates made of wood to facilitate transport. There were no pallets, cardboard boxes, or forklifts. Barrels had to be manually handled. Some regions began to employ pulleys to make the processes more effortless, but the service still required a lot of manpower.

The use of containers also decreased product loss since inadequate cargo packaging damaged goods and led to cargo deviation, in addition to high handling costs. Loading and unloading on ships accounted for roughly half of the total cost of transporting a product at the time.

It can be argued that the invention of the container revolutionized foreign trade, as it streamlined the transport of goods between countries, as it facilitated loading/unloading, contributed to reducing damage, and enabled the transportation of different types of goods on the same ship.

Main characteristics of containers

The first containers, created by Malcom McLean, measured 33 feet (a foot – a measurement system used in the United Kingdom, the United States, and, less frequently, in Canada – is the equivalent of 12 inches).

Currently, containers have been standardized in 40 and 20 feet. The 20-foot container is used as the unit of measurement (TEU, 20-foot equivalent unit).

The primary distinction between a 20-foot and a 40-foot container is its length. A 20-foot container has an internal length of 5.9 meters, whereas a 40-foot container has an internal length of 12 meters.

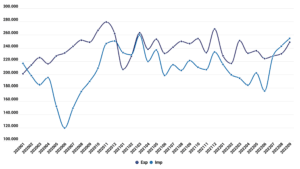

The chart below, drawn from data from DataLiner, Datamar’s market intelligence tool, shows the movement of containers in Brazil in the last three years:

Source: DataLiner (click here to request a demo)

See below the characteristics of the main container models currently available. There are also other models for different needs:

20-foot dry container: used for dry cargo, the 20-foot container has internal measurements of 5.900 m long X 2.350 m wide X 2.393 m high, with a cubic capacity of 33.2 m. It can contain up to 24,000 kg.

40-foot dry container: also used for dry cargo, it is larger than the 20-foot container. It is 12.032 m long X 2.350 m wide X 2.92 m high, with a cubic capacity of 67.7 m. It has a maximum capacity of 26,930 kg.

40-foot high-cube container: Indicated for transporting large amounts or customized project cargo, due to its different height and width. Its internal measurements are 12.032 m long X 2.352 m wide X 2.698 m high, with a cubic capacity of 76 m. It can contain up to 26,330 kg.

Tank container: used for the transport of chemical products, highly corrosive products, and acid cargo loads. It usually is coated on the inside and is 5.717 m long X 2.267 m wide X 2.117 m high. It has a maximum capacity of 24,000 kg and 27.4 m³.

20- and 40-foot reefer containers: ideal for cargo that requires constant below-zero temperatures or temperature control, such as meat and fruits. The internal dimensions of the 20-foot model are 5.444 m in length, 2.294 m in width, and 2.276 m in height, with a cubic capacity of 28.4 m. The maximum weight is 22,360 kg.

The 40-foot model measures internally 11.561 m in length X 2.268 m in width X 2.249 m in height and has a cubic capacity of 59.3 m. It has a maximum capacity of 26,000 kg.

Refrigerated cargo

The reefer container deserves special attention because it transports a large portion of Brazilian exports. In recent years, the country has emerged as an important international supplier of animal protein, and the reefer container was critical to ensuring that exported products arrived in good condition at their destination.

Aside from the increased demand for refrigerated containers, at the height of the Covid-19 pandemic, jumbled global maritime logistics caused such containers to lack, and booking them became highly competitive – which had a significant impact on exporters.

In addition, Brazil faces an issue regarding the imbalance between Brazilian exports via reefer containers versus imports. To meet this demand, some actions were taken. One of them is the use of disconnected reefer containers to import dry cargo, known as NOR (Non-Operating Reefer), since transporting empty containers inside ships generates high logistical costs and directly impacts freight. Another alternative was the use of reefer ships in some cases.

In recent years, shipowners have also made investments in refrigerated containers to increase their fleet.

See below the movement of reefer containers in Brazil in the last three years. The graph was created with DataLiner data: